CNC Parts

Objective: Develop CAD and CAM models using Fusion 360 software to acquire proficiency in CNC milling operations.

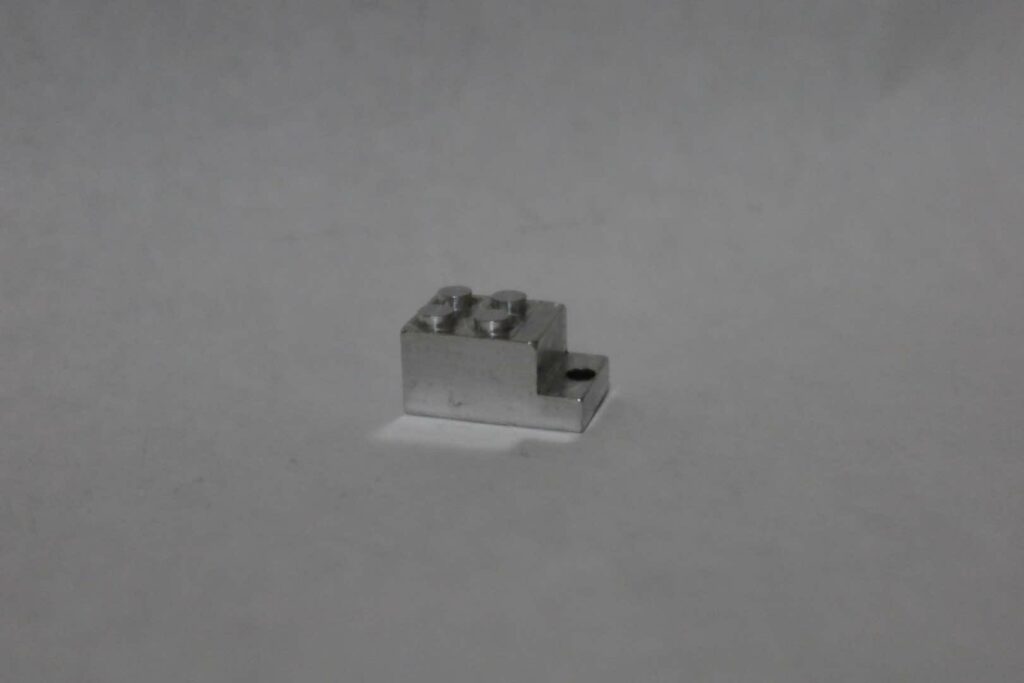

The first CNC component I produced was a keychain LEGO brick. Utilizing a technical drawing sourced online, I replicated the design of a 2 x 2 x 2 LEGO brick and incorporated an extrusion with a hole for the keychain attachment. Transitioning to CAM mode, I generated the toolpaths required for the milling process. I used a 1/2″ flat endmill to face and a 1/8″ flat endmill for the cuts around the press-fit studs. Subsequently, I employed a manual mill to remove excess material and achieve a smooth finish.

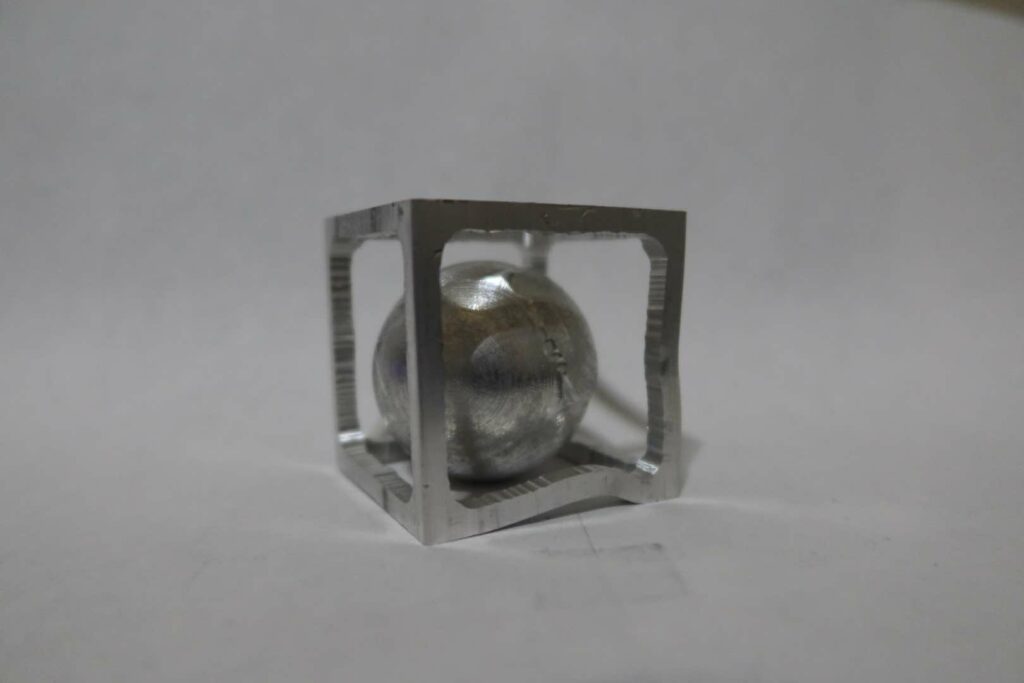

The Ball in the Box project involved machining a 4 in x 4 in cube to leave a spherical shape that fits within the hollowed cube. This process required removing material from between the cube’s faces and the ball’s surface. After completing one face, the stock was rotated until only one face remained. For the final face, a 3D-printed “cradle” was positioned in the vise to support the cube, allowing the last face to be milled. Once the toolpath was finished, the ball was fully separated from the stock and could move freely within the cube.

The primary lesson learned from this process was the importance of moderating the clamping force applied to secure the part. Excessive clamping pressure caused the 3D-printed cradle to deform, which, in turn, led to distorted edges on the box.