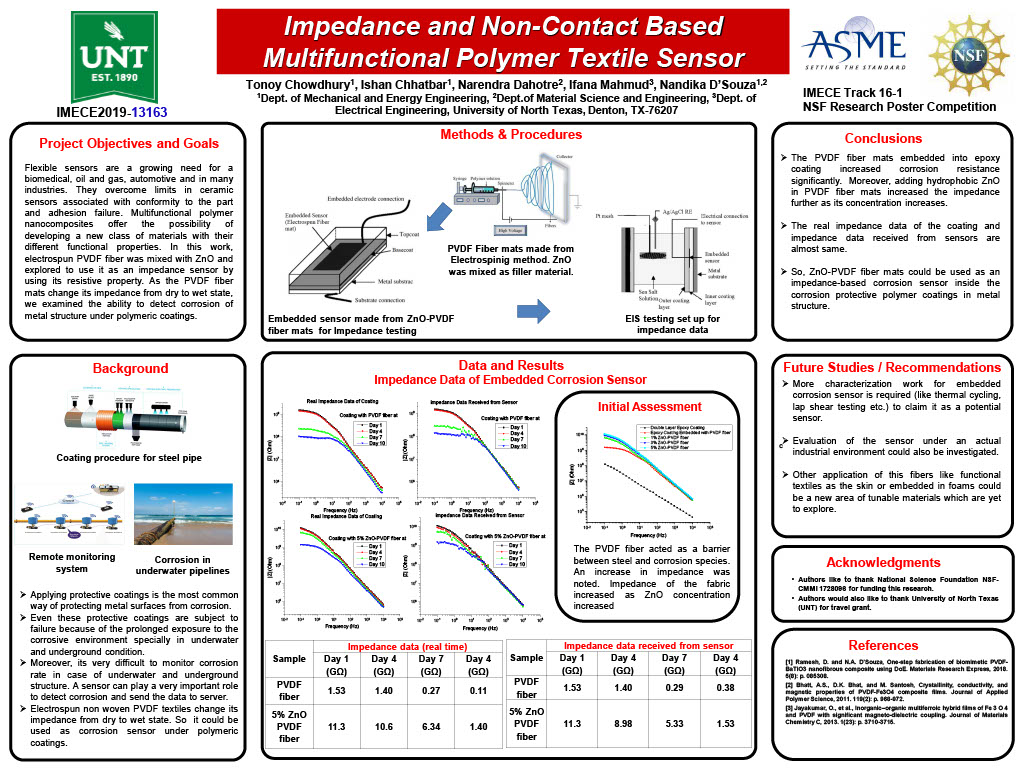

Corrosion Sensor Prototyping

Objective: Prepare corrosion sensor samples to investigate the effect of varying zinc concentrations in electrospun PVDF fibers on sensor performance by monitoring changes in resistance.

Creating Coupons: Using a drop saw, steel coupons with the dimensions of 50 × 25.4 × 3.2 mm were cut from a steel stock. These coupons were then polished using 240 and 600 grit sand paper, washed, and left to air dry.

Electrospinning: I used syringe pump set to feed at 0.05 mL/hr to pump the various the PVDF and Zinc solutions in a 5 mL syringe. The solution was fed to an aluminum foil-coated rotating roller which carried a voltage of 15 kV (from a DC power supply) to complete the electrospinning process.

Sample Completion: The PVDF and Zinc fiber was divided into smaller samples sizes. Silver paste was applied to the small fiber samples to adhere a copper wire to test impedance changes. These fibers were then baked at 100 °C for an hour.

While the fiber was in the oven, epoxy resin was applied to the steel coupons and left to harden. Once hardened, the PVDF fiber is placed and a top coat of epoxy is applied to complete the sample fabrication.

The published literature can be found here: Embedded Corrosion Sensing with ZnO-PVDF Sensor Textiles