Line Operator Toolkit

Objective: Improve organization and update safety for operators working on the manufacturing floor to the 5S standard.

My strategy for enhancing safety standards involved designing two types of toolkits, enabling operators to efficiently and securely store the tools needed for the line.

After consulting with line operators, I identified the most frequently used tools as metal scrapers, scissors, metal brushes, trims, and 90° bent picks.

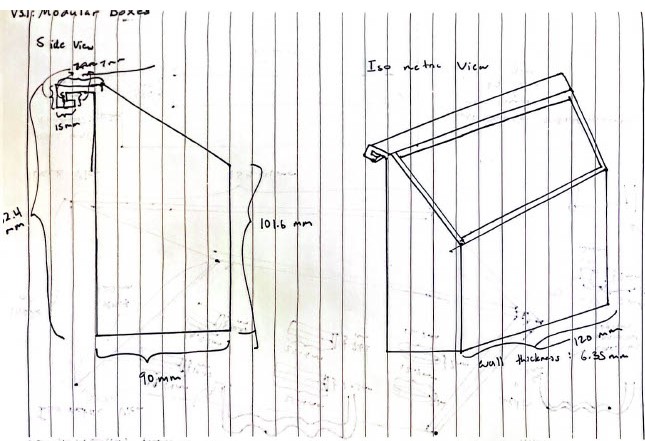

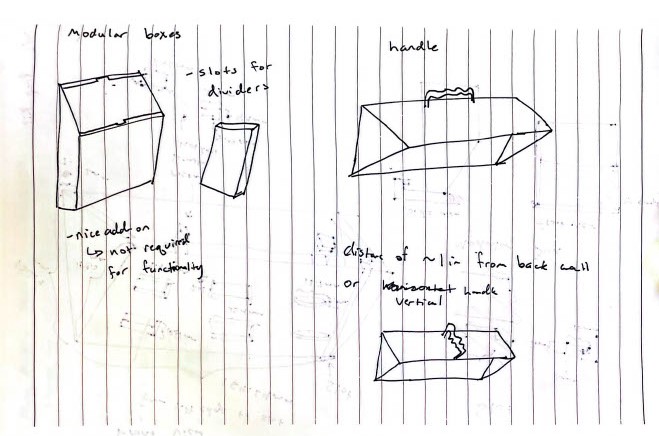

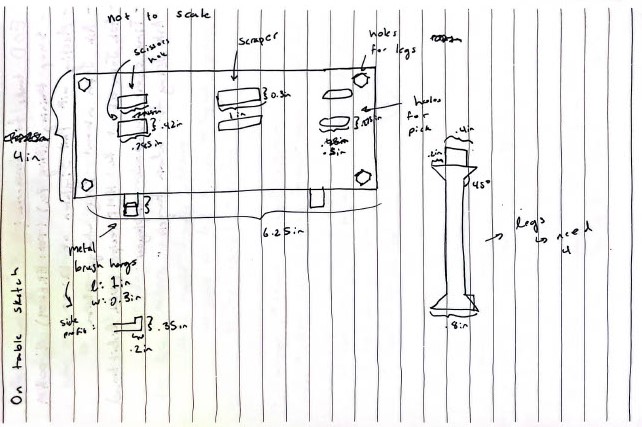

Stationary Toolkit: This toolkit is designed to be mounted on a table. It features a structure with four columns that slot into place and a flat face with holes for tool suspension. The toolkit’s modular design allows for adaptation to the changing needs of the operators. Additional tools can be accommodated by modifying the flat face. After making these adjustments, the columns can be reassembled into the updated design.

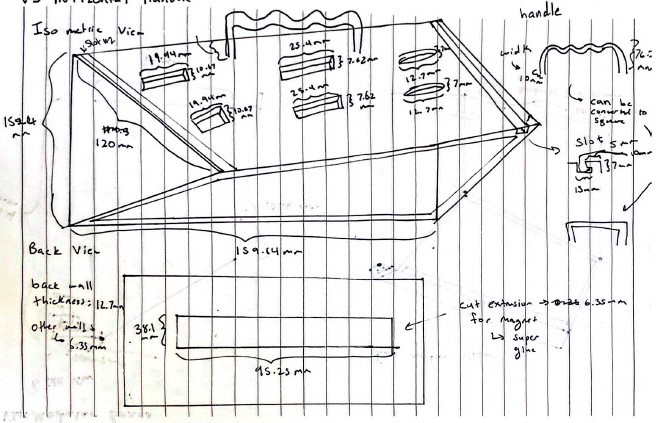

Line Toolkit: This toolkit is designed for portability, enabling operators to transport it around the line. The top face features holes for tool suspension and includes a handle for convenient carrying. Instead of a rectangular middle section, a triangular design was implemented to facilitate the removal of dust and debris while optimizing print orientation for minimal support requirements (printed at a 45° angle). In line with the modular concept, interference-fit slots were incorporated for additional storage compartments. Additionally, a magnetic strip on the backside allows the toolkit to be attached to metal surfaces, enhancing tool accessibility.